By Claire Hutchins, USW Market Analyst

U.S. Wheat Associates (USW) believes customer engagement, supply chain transparency and free access to market information are the building blocks for robust relationships with U.S. wheat overseas customers. Every year, USW hosts several foreign trade delegations on trips to the United States to help foster these relationships. These delegations of millers, bakers, wheat buyers and executives from overseas mills and end-product manufacturers visit many stops along the U.S. wheat supply chain including wheat farms, state wheat commissions, export inspection facilities, export elevators, test labs, wheat breeding programs, bakeries and more. These trips are designed to assure overseas customers of the quality, abundance, end-use versatility and value of U.S. wheat.

This week, I joined my USW colleagues in Portland, Ore., who hosted a trade delegation of milling executives, including vice presidents, marketing directors and quality control and plant managers, from the Philippines. Many participants were from companies that are customers of U.S. wheat, yet had never been to the United States themselves. On day one, I asked each participant about what they wanted to learn on the 10-day trip. Interests ranged from supply chain management to best practices in flour milling and quality control measures to visiting export terminals and wheat farms Others were looking forward to learning more about quality benchmarks at U.S. bakeries and discussing new marketing insights which could appeal to the growing “foodie” generation of Filipino consumers. Each trade delegation experience is a little different, but each offers a variety of tours, meetings and seminars to address the diverse needs of each group.

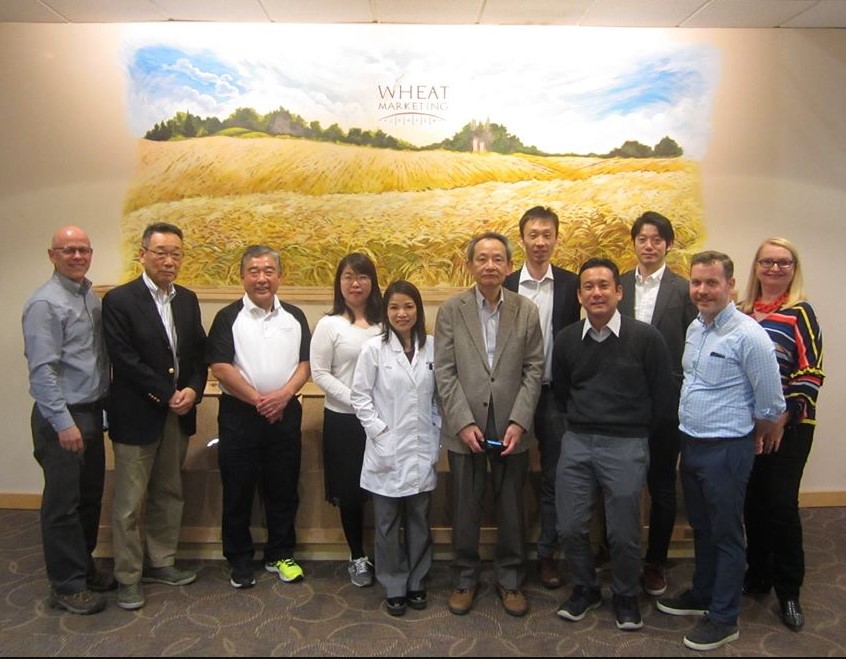

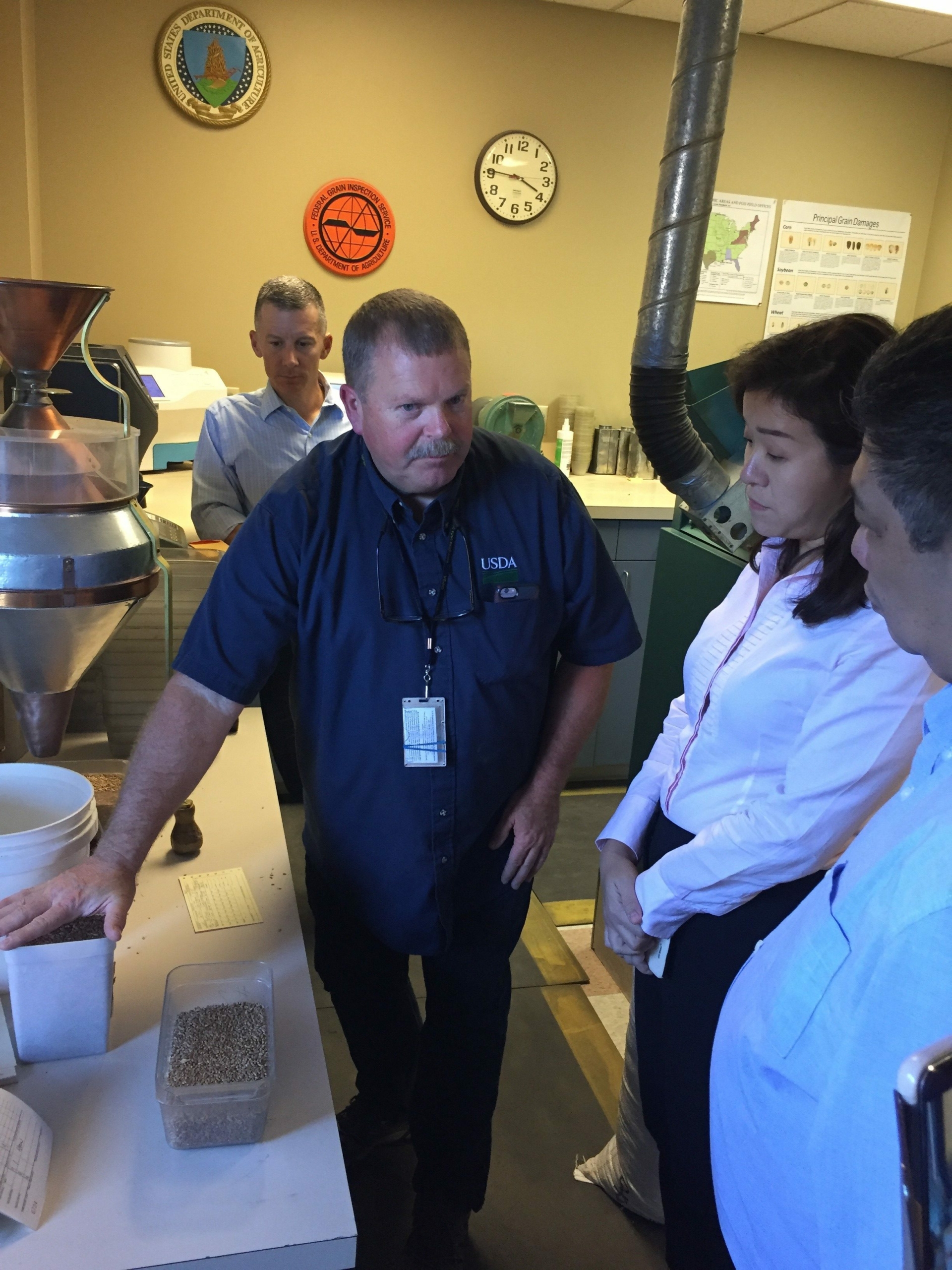

The delegations first visit was to the Wheat Marketing Center (WMC), where they met Managing Director Janice Cooper, Technical Director Dr. Jayne Bock and a team of technical specialists. WMC demonstrates U.S. wheat quality and marketing differentiation by providing flour and end-use research and technical training. The delegation watched WMC specialists use a new solvent retention capacity (SRC) testing machine that creates a “fingerprint” analysis of the wheat. The delegation was very interested in the test’s ability to accurately predict end-use functionality for high volume samples of soft and hard wheat flours. Participants emphasized that flour consistency is a high priority for consumers and wanted to know more about research in the United States addressing this issue. WMC staff explained that U.S. wheat farmers use precision agriculture tools to better regulate and monitor nitrogen application, which minimizes fertilizer waste and helps stabilize wheat protein levels. WMC is also conducting tests to determine if wheat with different protein levels can be still be used to create similar end-products like cakes and cookies. Members of the delegation also asked about recommended wheat and flour tests, significant issues facing the future of consistency in wheat production and what is next for the future of wheat quality testing.

Watching a demonstration at the Wheat Marketing Center.

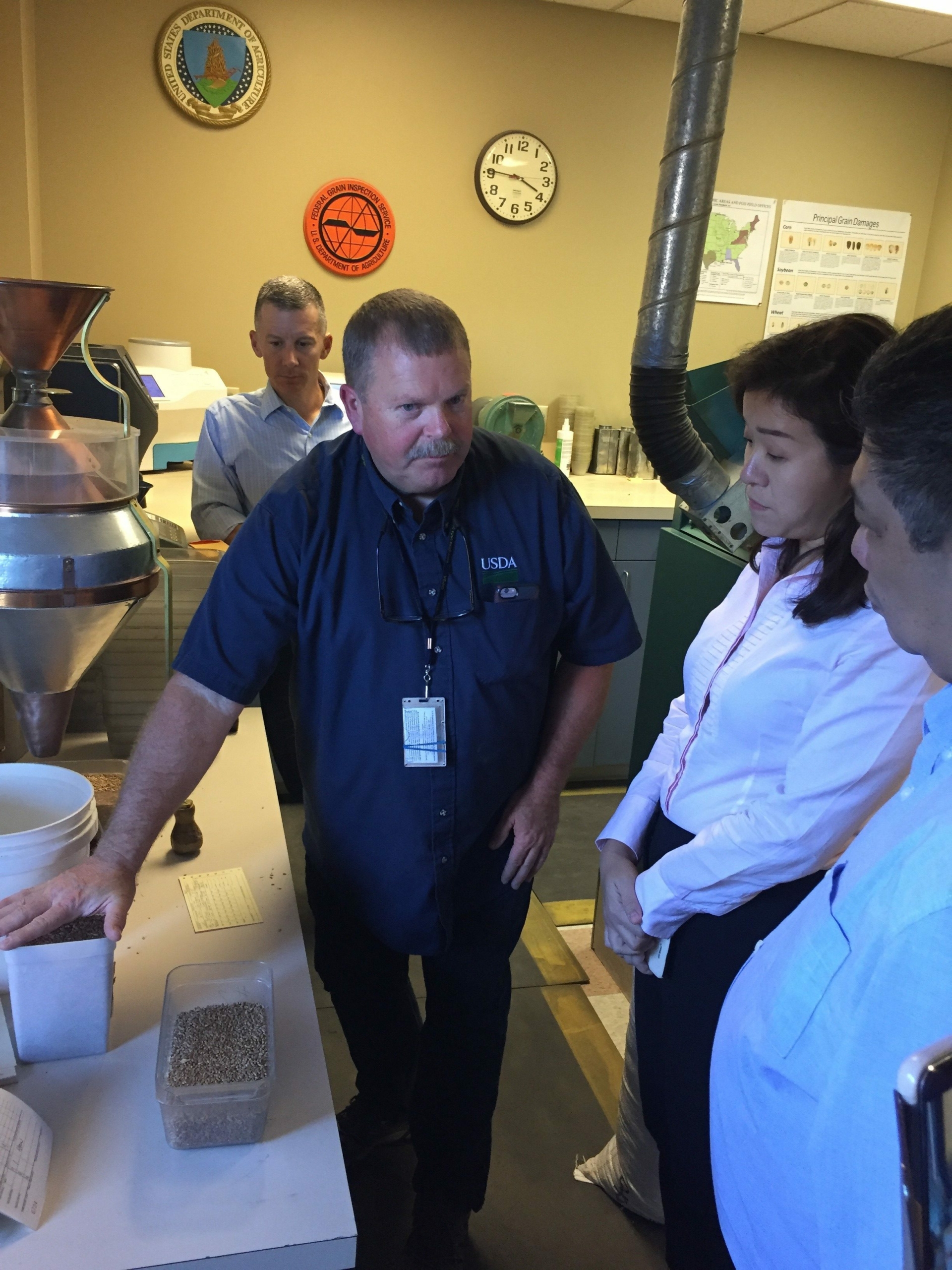

Next, during a tour with the Federal Grain Inspection Service (FGIS), the delegation had a first-hand look at the third-party, impartial testing procedures conducted by government inspection specialists at export elevators. FGIS falls under the USDA’s Agriculture Marketing Service and assures, through rigid testing procedures, the quality and quantity of every grain order placed through U.S. export terminals. Through random sampling, compared to the size of the wheat shipment, FGIS specialists test for moisture, protein, unusual odors, insects, dockage, test weight, shrunken and broken particles, class and dark hard vitreous levels of each outbound wheat shipment.

Touring FGIS with commodity grader, Sam Stanley

At the Oregon Wheat Commission (OWC), the delegation met with Walter Powell, Oregon wheat farmer and OWC chairman, and Blake Rowe, OWC chief executive officer. Together, Powell and Rowe gave an excellent presentation on Oregon’s soft white (SW) wheat crop quality and marketing conditions, trade issues facing the industry and the Commission’s Wheat Quality Program. They explained that the program creates a “quality loop,” in which public crop quality data is used to inform customers, whose feedback in return directs private and public wheat breeding initiatives to improve end-use versatility and value. Powell and Rowe assured the delegation that customers have ownership in the quality development process by voicing their unique needs to members of the U.S. wheat industry.

The delegation started its second day at Franz Bakery, a large-scale U.S. bakery that services grocery stores, schools and chain restaurants in the Pacific Northwest (PNW). At the 113-year-old Portland facility, the delegation asked about marketing techniques, product differentiation and transportation logistics that allow the bakery to maintain its large PNW presence. Jodie Kelley, a Franz Bakey tour guide, emphasized that the business has been family-owned and operated since its inception, which gives it a unique marketing edge in the United States. By offering a variety of products, the bakery caters to a large customer base, including fast food chains and customers with different dietary restrictions and preferences.

The delegation’s next stop, Little T Bakery—a small, artisan bakery—gave the team a more intimate look at end-use versatility for locally-sourced SW wheat, spelt and whole-wheat flours. Unlike Franz Bakery, Little T Bakery caters to a much smaller community, baking only what it needs for the day and distributing minimally to local restaurants. Participants were greeted by the owner and baker, Tim Healea, who talked about local wheat sourcing and the challenges of marketing simple, traditional recipes in a trend-oriented industry. Team members asked about the popularity of GMO-free and gluten-free products. Healea believes the trend in gluten-free labeling is on the decline and does not market gluten-free products in his bakery.

Sampling artisan bread goods at Little T Bakery with owner and baker Tim Healea.

After the bakery tours, the delegation visited United Grain Corporation (UGC) export elevator, the biggest in the PNW at a 220,000 metric ton total storage capacity. UGC grain traders took the delegation through the technical control room that oversees all yard operations, the inspection facility that performs similar quality tests to FGIS, the rail unloading yard and the barge unloading dock. Participants asked questions about insect control, grain cleaning, quantity differentials at loading, the effects of rail costs on export and country elevator prices and the potential for rain damage during loading. At lunch, with members of the Pacific Grain Export Association (PGEA), UGC traders and a trader from Columbia Grain International gave crop quality reports on SW and hard red spring (HRS) wheat—top classes imported by the Philippines. In marketing year 2018/19, the Philippines was the largest importer of U.S. HRS and SW wheat and the second-largest overall importer of all U.S. wheat classes. The delegation was interested in hearing the traders’ long-term projections for SW wheat growth in the United States and traders shared that production should remain stable in the future as white wheat remains a “boutique” wheat on the global market, is unique to the PNW and highly valuable as an exportable commodity. Traders also forecast that customers will have access to large available supplies at reasonable prices as harvest in the PNW starts in the next few weeks. In return, to better understand the needs of their customers, traders asked the delegation about common blending practices, potential fumigation issues at delivery and vessel delays.

Touring UGC Vancouver, WA, export facility.

During the next eight days of their trip, the delegation will travel to Washington to visit wheat farms, a grain barge loading terminal, Washington State University’s Western Wheat Quality Lab and the Washington Grain Commission. Next, they will head to Idaho to visit a flour mill, a country elevator and the Idaho Wheat Commission. Finally, the delegation will finish its tour in Nebraska, where they will visit more wheat farms, another flour mill and the Nebraska Wheat Board.

Follow USW on Facebook and Twitter for pictures and updates about the delegation’s travels.