What to Know About Clean Label and Implications for Wheat Food Production

Editor’s Note: Important work has been done indicating that U.S. hard red spring (HRS) is a potential “clean label” ingredients for the world’s commercial bakers. To help wheat buyers understand more about this opportunity, U.S. Wheat Associates (USW) is reprinting the following post originally published in October 2021.

The concept of “clean label” products is complex but increasingly important in food production and marketing. A blog by the chief science and technology officer for the U.S.-based Institute of Food Technologists (IFT) noted that clean label is not a scientific term.

“Rather, it is a consumer term that has been broadly accepted by the food industry, consumers, academics, and even regulatory agencies,” the IFT scientist wrote. “Essentially, clean label means making a product using as few ingredients as possible … that consumers recognize and think of as wholesome—ingredients that consumers might use at home … with easy-to-recognize ingredients and no artificial ingredients or synthetic chemicals.”

Familiar Example

Clean label has become associated with consumer trust in food producers. The main challenge associated with clean label products arises in part from regulations requiring labels to use scientific names for ingredients. Food makers know their ingredients are wholesome and safe, but the label may put off consumers without a scientific background. For example, the IFT clean label blog demonstrated the potential challenge for consumers who may be reading this familiar label: “Bleached Wheat Flour, Niacin, Iron, Thiamin Mononitrate, Riboflavin, Folic Acid Enzyme,” and not know that these are the scientific names for the ingredients in all-purpose flour found in homes around the world.

Expert Insight for the Baker

Food scientist Dr. Senay Simsek is well-known and respected by many of the world’s U.S. wheat end-product producers, serving as a USW consultant and as past head of the Wheat Quality & Carbohydrate Research Program at North Dakota State University (NDSU). Before her 2021 appointment as professor and Head of the Food Science Department at Purdue University, Dr. Simsek gave a detailed video presentation on the issue of clean labeling in the baking industry for USW’s 2020 U.S. Wheat Crop Quality program.

In that presentation, Dr. Simsek noted that the clean label concept is globally recognized. She cited a survey conducted in the Asia Pacific, Europe, Latin America, the Middle East and North America, indicating that almost half of consumers define clean label as “free from artificial ingredients.”

In studies at her NDSU program, Dr. Simsek had a graduate assistant identify all ingredients that can be found in baked bread products. In addition to flour and water, her team identified 53 different ingredients “with so many names that people have difficulty understanding like distilled monoglycerides or calcium peroxide, but which all have functionality.”

Dr. Simsek provided an in-depth look at many of the key ingredients and their bread baking functionality in the video. Noting the list of alternative dough strengthening ingredients, Dr. Simsek turned to the results of a study by her NDSU program comparing the performance of several alternative ingredient combinations.

The Clean Label Potential of Spring Wheat Flour

“The question was, can there an alternative to added chemical ingredients to strengthen the gluten structure in a way that is accepted by consumers and simplifies the label on white and whole wheat bread products?” she said.

The study used a commonly accepted winter wheat flour base as a control. Several formulations with spring wheat flour were added at different ratios to the base. Vital wheat gluten and different chemical dough strengtheners were also added to various formulations that were all baked and compared.

Dr. Simsek’s team at NDSU studied the effects on quality by adding strong gluten spring wheat to bread formulations compared to added dough strengthening agents. Replacing chemical agents with a simple flour ingredient could improve quality and simplify commercial baked product labels.

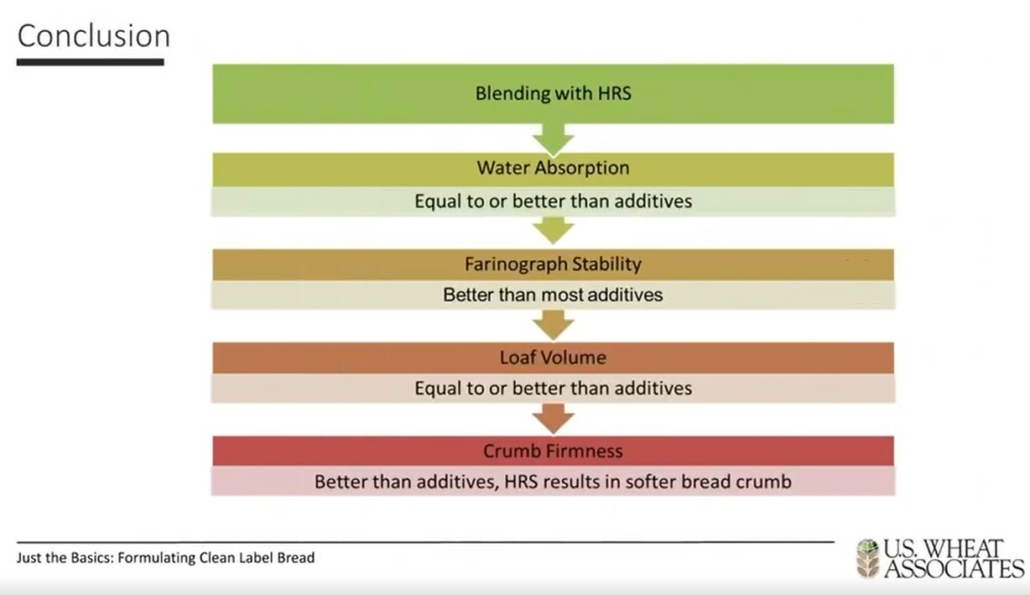

“In white bread, [crumb] firmness values were lower in the spring wheat blends compared to the control,” Dr. Simsek said in the USW video presentation. “If we just look at the bread comparing with chemicals versus the spring wheat blends, spring wheat blends were more functional, and they provided a better product compared to chemicals. Overall quality in terms of spring wheat blends versus the chemical, water observation was equal or better than additives, farinograph stability was better than additives, and the loaf volumes were equal or better than additives.”

Similar results were seen in whole wheat bread comparisons, Dr. Simsek said.

Noting that more investigation into the clean label potential of added strong gluten flour is needed to expand understanding, Dr. Simsek said, “the take-home message is that spring wheat could be a good option to replace oxidizing agents in bread formulations to have clean label bakery products.”