An Inside Look at IGP’s Flour Milling Short Course for Commissioners

The IGP Institute serves Kansas and U.S. agriculture through its global education center housed in the Grain Science Complex on the Kansas State University campus in Manhattan. Its mission is to provide technical, research-based training benefiting industry professionals globally and enhancing the market preference for U.S. grains and oilseeds. The emphasis is on educational and technical programs supporting promotion and export market development efforts.

From Feb. 25 to 27, 2020, four colleagues from U.S. Wheat Associates (USW) participated in an IGP short course on flour milling for wheat commissioners (farmers and grain trade representatives who serve on the boards of state wheat commissions) and staff. IGP tries to hold this course annually to educate members of the U.S. wheat industry in the basic principles of flour milling through classroom lecture and hands-on practical training in the Kansas State University milling and baking laboratories and the Hal Ross Flour Mill.

Here is an inside look at this fun and very enlightening course that has built, and will continue to build, greater empathy for and connections with overseas flour milling and wheat food processors among U.S. wheat farmers and grain traders.

Participants in the 2020 milling short course were (left to right around the table): Mark Fowler, Vice President of Global Technical Services, USW , and co-instructor; Amanda Hoey, Chief Executive Officer, Oregon Wheat Commission, Portland, Ore.; Nathan Larson, a wheat farmer and Kansas Wheat Commissioner, Manhattan, Kan., ; Lance Adams, Merchandising Manager, Team Marketing Alliance, Moundridge, Kan.; Steve Mercer, Vice President of Communications, USW; Jason Middleton, Oregon Wheat Commissioner and PNW Regional Manager, United Grain Corp., Umatilla, Ore.; Dana Tuckness, a wheat farmer and Oregon Wheat Commissioner, Ontario, Ore.; Shelby Knisley, Director of Policy, USW; Scott Yates, Director of Communications and Membership, Washington Grain Commission, Spokane, Wash.; Claire Hutchins, Market Analyst, USW; Brian Cochrane, a wheat farmer and Washington Grain Commissioner, Kahlotus, Wash.; Aaron Harries, Vice President of Research and Operations, Kansas Wheat, Manhattan, Kan.; Shawn Thiele, Interim Associate Director/Flour Milling and Grain Processing Curriculum Manager, IGP Institute, and co-instructor.

Mark Fowler counsels his colleagues Shelbi Knisley and Claire Hutchins on adjusting laboratory mills in K-State’s Shellenberger Hall in a section of the course demonstrating basic milling processes. Hutchins is adjusting the break roll gap on the lab mill.

Measuring and adjusting “Break Release” to balance the milling system is a basic skill for flour millers. Here in the Hal Ross Flour Mill, Shawn Thiele explains how weighing stock from 1st break rolls, sifting and comparing the weight of the resulting flour (“through material”) measures the percentage of break stock released.

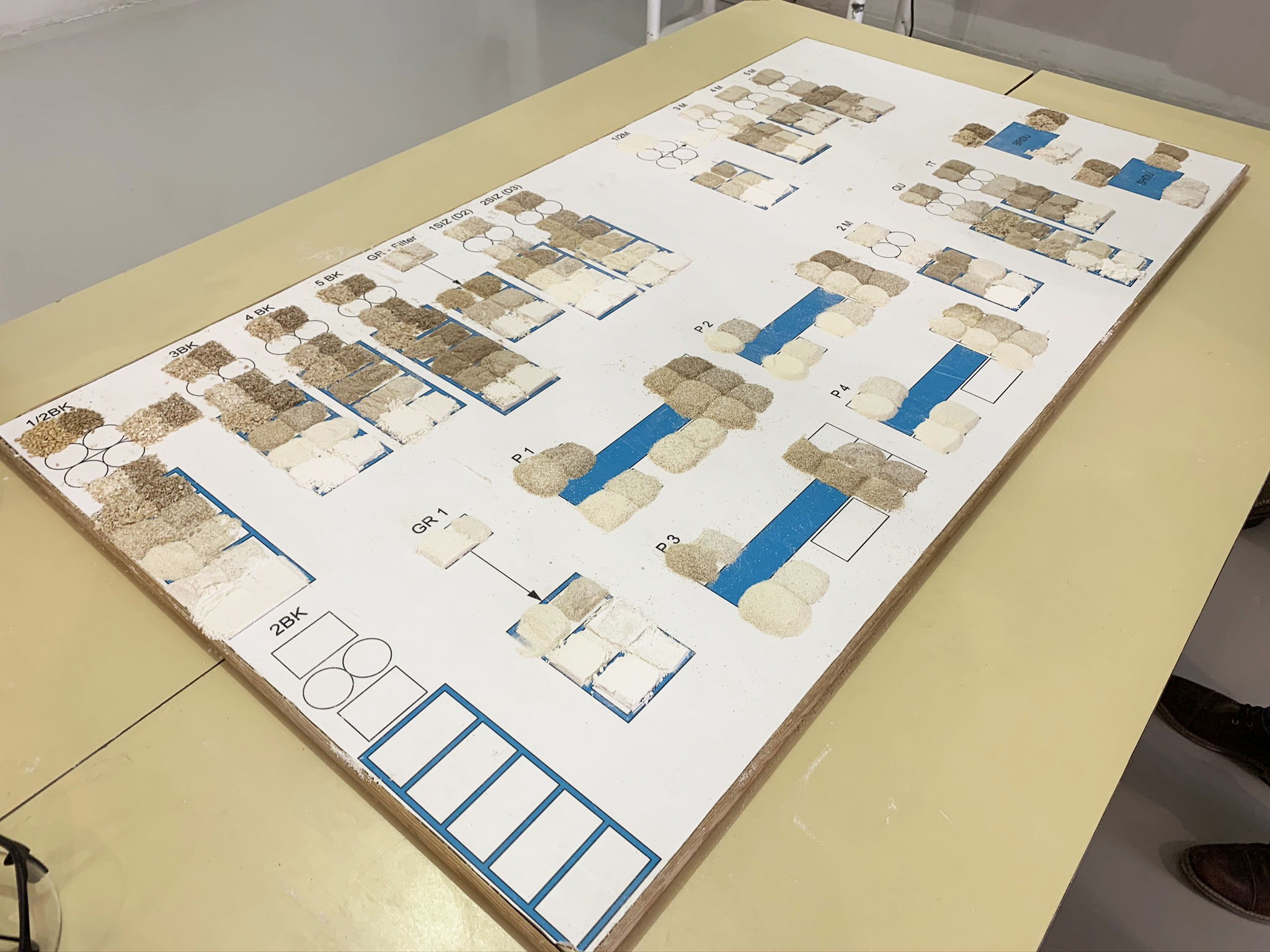

Comparing particle size and color of “through” material from the break, purification and reduction systems clearly show the fine-tuned effort at each step in the milling process to extract as much usable flour as possible from cleaned and tempered wheat stock.

Participants in the short course learned about the wide range of flour qualities and byproducts produced in the milling process. This sample table was prepared for course participants by students at K-State working toward bachelor’s degrees in milling science and management.

One wheat does not fit all. Preparing and baking sugar snap cookies (biscuits), yellow cakes and pan breads using different flour products helped the course participants better understand flour functionality and the crucial wheat quality component for end-product processors around the world. Aaron Clanton, left, Bakers National Education Foundation (BNEF) Instructor at K-State, and several Bakery Science students led the participants through an enjoyable morning in the K-State bakery lab.