African Trade Team Explores U.S. Wheat Supply Chain, Meets Farmers in Kansas, North Dakota and Minnesota

Wheat buyers from Nigeria and Kenya join North Dakota Wheat Commissioner and farmer Scott Huso in one of his fields to get a look at this year’s crop.

Pictured above at the Port of Duluth in Minnesota: Chad Wiegand, USW Regional Director for Sub-Saharan Africa; Vigneswaran Sinnathurai, Vice President of Milling at Olam; Alok Khator, Vice President and Regional Manufacturing Head at Olam; Savan Sunil Shah, Director at United Millers LTD; Coreen Berdahl, Vice President of Operations at Minnesota Wheat.

Buyers from two African markets that are very different – yet equally important to U.S. wheat farmers – recently took a close look at the hard red winter (HRW), hard red spring (HRS) and hard white (HW) wheat supply chain by visiting farms and facilities in Kansas, North Dakota and Minnesota.

Led by U.S. Wheat Associates (USW), the trade team included representatives of companies in Nigeria and Kenya. Nigeria is an established customer and the fourth-largest importer of U.S. wheat. Kenya, a developing market that has seen a steady increase in wheat foods consumption, holds great potential for U.S. wheat.

Farm to Export Elevator

The team was able to follow the entire process of how U.S. wheat moves from farm to export elevator.

“Our goal was to show them the U.S. supply chain. We also wanted to explain how the quality of wheat grown in the states is monitored through the inspection process,” said Chad Weigand, USW Regional Director for Sub-Saharan Africa. “These visits are very important to customers in Africa who want to be assured they are getting the quality they want. We have competition in these markets, and face-to-face visits go a long way in providing trust and confidence in wheat from the U.S.”

Those face-to-face visits included meeting farmers. Kansas Wheat, an important USW partner, hosted the African team for visits with wheat growers and stops at the Kansas Wheat Innovation Center and USDA’s Center for Grain and Animal Health Research. During a visit to the IGP Institute, the team learned about technical training and assistance programs. A commercial flour mill in McPherson was also a key aspect of the visit.

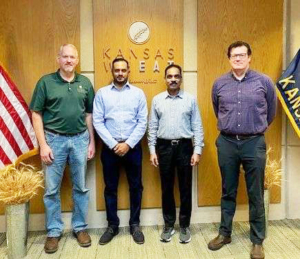

Kansas Wheat hosted the African team to showcase the U.S. wheat supply chain. Pictured (left to right) are Kansas Wheat Vice President of Research and Operations Aaron Harries; Savan Sunil Shah; Vigneswaran Sinnathurai; and Chad Weigand.

Building Upon a Solid Base

Flour milling training is an important part of USW’s efforts in Africa.

“We provide a lot of help to the flour milling industry there, particularly by working with up-and-coming millers who are just learning the trade,” explained Weigand. “By providing technical assistance in grain analysis, test milling, flour analysis and test baking, U.S. Wheat is helping grow the milling industry. It increases millers’ knowledge of U.S. wheat classes. Ultimately, the purpose is to show advantages of each U.S. class over competitors’ wheat. We also work with the flour industry to address trade policies – things like import requirements and other market access issues.”

In Kansas, the team also made a stop at the Federal Grain Inspection Service (FGIS) facility in Kansas City.

Before Kansas, the team met with wheat farmers and received an update from the Northern Crops Institute (NCI) in North Dakota. The Minnesota portion included meetings with grain traders at CHS and a tour of port loading facilities in Duluth. Coreen Berdahl, Vice President of Operations at Minnesota Wheat, participated in the Minnesota.

Supply Situation Updates

Farmers and representatives from Kansas Wheat acknowledged that Nigeria and Kenya will be limited by the short supply of HRW wheat this year. But building and maintaining relationships is important to global customers.

“Harvest results may differ from year-to-year, but coordinating local visits directly connects our customers with farmers committed to growing high-quality wheat,” said Aaron Harries, Vice President of Research and Operations for Kansas Wheat. “Wheat buyers, millers, and bakers track the progress of our wheat crop each year. Moving past the headlines is important to communicating the quantity and quality of each year’s harvest.”

On its final night in Kansas, the African trade team was hosted at a dinner, where buyers from Nigeria and Kenya were able to meet with Kansas Wheat staff and U.S. wheat farmers, including USW Chairman Michael Peters of Oklahoma.

Markets Differ, Both Have Potential

The U.S. has been the top wheat supplier to Nigeria in two of the past five years. Nigeria has been the largest buyer of HW and second-largest buyer of HRW.

In 2021/22, U.S. wheat exports to Nigeria increased to 1.63 million metric tons (MT) and the U.S. market share was 30%. But high prices have hurt trade in 2023.

Kenya, on the other hand, is seeing growth in wheat demand due to increased urbanization. New products are being introduced and branded for specific end-uses: chapati flour, mandazi flour, self-rising flour, and others.

Most of the wheat flour in Kenya is used for home baking of chapatti (flat bread).

As both the Nigerian and Kenyan markets evolve, USW plans to share information about U.S. wheat’s quality and reliability.

“We will continue working on relationships and sharing information about the quality and reliability of U.S. wheat,” said Weigand. “We will also demonstrate to millers, bakers and end-product manufacturers the advantages of all six classes of wheat as stand-alone or blending wheats to reduce costs by displacing competitor wheats.”

This article includes information previously shared in an article by Kansas Wheat.